close

Shirt In Reality

01 MATERIALS 01

CHOYA SHIRT and Toyobo successfully cultivated a hybrid cotton seed from sea island cotton and pima cotton. Shirts made from this hybrid cotton known as Master Seed® had the luster and soft touch of sea island cotton while maintaining the long, strong threads of pima cotton.

02 SPINNING

At the end of the 19th century, Japan’s Toyobo was the first company in Asia to incorporate industrial spinning. Today, they use the superfine Master Seed® cotton produced in their domestic factory (Inami) to create high quality materials.

03 PATTERN 03

We use patterns that incorporate our original lines and high-level 3D designs using complicated curves to create a soft fabric that fits your body to create a beautiful silhouette while also allowing for extremely comfortable movement.

04 SEWING

We have “10 machine-made provisions” to create unmatched accuracy for size-specs.

Slow speed 3D sewing: The perfect needle: Single Needle: Extremely fine hem sewing: Set In Sleeve: Blind Stitch: Radial Square Type Button Holes: Run And Turn: Neck wrapping: Original white-lipped pearl oyster buttons:

The Shirt

01 PHOTOGRAPHER SHIRT

Atsushi Nakamichi – Architecture Photographer

“One photographer I truly respect is Irving Penn, and in his self portraits he would always wear a white shirt, which I believed was a way for him to show respect towards the subjects. After I put my arms through this refreshing shirt, I finally felt I had moved a little closer to my photography idol.”

02 ARTIST SHIRT 02

Shungetsu Nakamura – Flower Artist

“I am often invited to parties to which I bring a special flower arrangement, and I was always looking for a shirt that was comfortable to move in but not too informal. Regardless of the beautiful fabric and force on details, the shirt never loses its shape. This is just what I was looking for.”

03 CHEF SHIRT

Shinichi Sato – Chef, Co-owner Passage 53

“I have a preference for minimal silhouettes that fit the body, and I would often order shirts bespoke from well-established Paris shirt shops. But the made-in-Japan CHOYA shirts include all the nuances I have been unable to vocalize, and I have no doubt I’ll be holding on to these for a long time.”

Dream For Shirt

01 Innovation × Passion × Tradition = Future

Coupling the strength to search for innovation with our passion creates new traditions for the next generation.

02 Subtle, Precise, Sincere Creation

Create materials from scratch, use the ultimate pattern model, incorporate logical stitching, use the newest machines with tried-and-true techniques to create a balanced sensitivity.

03 Bespoke Power

With selflessness and keen judgement, we produce a unique piece tailor-made for each customer.

Collection For Pitti UOMO

01 Materials

Raw cotton: To make CHOYA SHIRT’s foundational principles possible, being able to grow and store strong and beautiful cotton was a necessity. In 1993, after years of collaboration, CHOYA SHIRT and Toyobo successfully cultivated a hybrid cotton seed from sea island cotton and pima cotton. Shirts made from this hybrid cotton known as Muster Seed® had the luster and soft touch of sea island cotton while maintaining the long, strong threads of pima cotton.

02 Spinning

At the end or the 19th century, Japan’s Toyobo was the first company in Asia to incorporate industrial spinning. Today, they use the superfine Muster Seed cotton produced in their domestic factory (Inami) to create high quality materials.

03 Fabric

From the end of the 19th century until now, fabrics are woven in the cotton fabric production area of Hamamatsu. With a shuttle weaving machine, fabric are slowly woven to maintain the softness of the material.

04 Processing

To maintain the beauty of the original cotton and lush feel of the fabric, we use rotation manufacturing as often as possible. With a gentle two-stage bleaching system, we create beautiful white fabric with a soft and silky finish.

05 Pattern&Model

By carefully examining our 130 years worth of pattern paper and using the wisdom we have gained through existing pieces and original bespoke pieces, we created our own original pattern. We use patterns that incorporate our original lines and high-level 3D designs using complicated curves to create a soft fabric that fits your body to create a beautiful silhouette while also allowing for extremely comfortable movement.

Sewing Method

01 Slow speed 3D sewing

In order to maximize the beauty of our 3D curved patterns, we set the sewing machine to ½ of the normal speed and sew without any pauses to create a beautiful sewing flow.

02 The perfect needle

We use a needle that is a perfect fit for the material taking into account the sensitivity, stitch-depth, etc. (24 / 30mm)

03 Single Needle

For the sides of the garment body and sleeves, we use a single needle. It not only looks beautiful, but creates a flexible texture that both is comfortable and feels nice on the skin.

04 Hem

Extremely fine (2mm) hem sewing

05 Set In Sleeve

After sewing the garment body and sleeves separately, we sew the sleeves in through the armholes while rotating them to create a beautiful fit to the body while also allowing for a large range of motion.

06 Blind Stitch

Using our in-house unique sewing machine we create a blind stitch that looks handmade. (First of its kind)

By stitching the fabric at an extremely slow speed to reduce tension, we increase strength and elasticity, allowing for completely even stitching impossible to create by hand while also being highly functional.

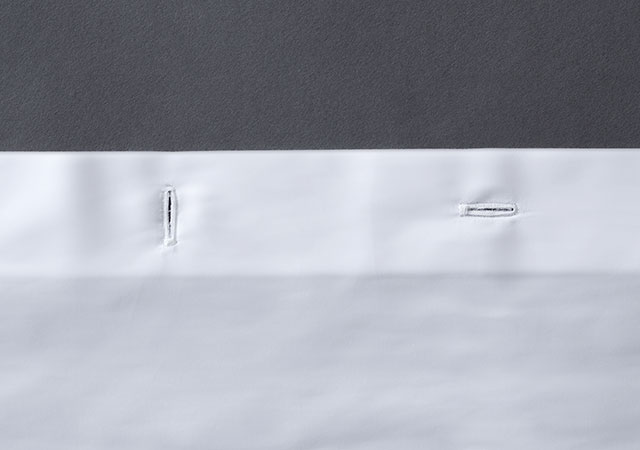

07 Radial Square Type Button Holes

Superfine thread count at high density. Radial curve on one side makes both a functional and beautiful button hole.

08 Neck Wrapping

We use a neck-wrapping method for the neck, cuff and all the garment body buttons with our unique sewing machine.

09 Run And Turn

Returning back after sewing one edge of the fabric is a method that requires high skill and much effort. For the front shoulders and cuffs, using the run and turn method creates a flat surface that feels and looks great while also being highly durable.

10 Original white-lipped pearl oyster buttons

With a beautiful shine and smooth feel, our white-lipped pearl oyster buttons are rounded at the bottom to make for simple and stress-free buttoning.